The unique flow design of the main work area, dust, reagent weighing, packaging in the equipment, can control dust, reagent spilt, rise, prevent dust, reagent inhalation harm to the human body

Weighing Room Sampling Booth for Raw Materials Weighing Booth Design

Weighing room Product features:

1. Equipment features and uses

Anne Parker negative sampling booth for raw materials is a special local clean room equipment for pharmaceutical, biological research and scientific experiments, which provides a vertical unidirectional air flow, part of the clean air circulation in the work area, and part of the discharge to the nearby area, so that the work area produces negative pressure, prevent cross-contamination, and ensure a high cleanliness environment in the work area.

2. Wind speed automatic frequency conversion system, so that the wind speed in the main working area is always in uniform and stable operation

3. Filter differential pressure display device, real-time monitoring of the effective operation of each filter.

4. Unique air duct design, effectively control the machine noise.

5. The unique flow design of the main work area, dust, reagent weighing, packaging in the equipment, can control dust, reagent spilt, rise, prevent dust, reagent inhalation harm to the human body, but also avoid dust, reagent cross pollution, protect the external environment and indoor personnel safety. The weighing operation area is protected by a 100-stage vertical laminar flow IS05 (NF, EN, ISO 14644-1).

6. Use environment and conditions:

Temperature 5 °C ~ 40 °C

Relative humidity not more than 85% (no condensation)

Atmospheric pressure 86kPa~106kPa

Power supply AC 380V, three-phase, 50Hz

Technical parameters:

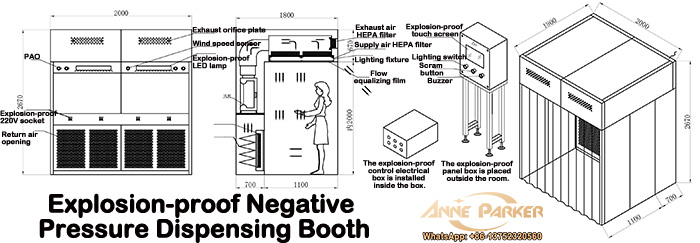

1. Inner size: 1900(L)*1100(W)*2000(H)

External dimensions: 2000(L)*1800(W)*2670(H)

2. Main material: 1.2mm thick SUS304# sanding stainless steel plate bent and formed

3. Rated air volume (m³/h) 2710~4100

4. Outlet wind speed (m/s) 0.45±20%

5. Rated power (kw) 4.6 (including spare socket)

6. Noise (dB(A)) ≤79

7. Built-in LED lighting ≥300

8. Power supply 380V, 50Hz

9. Control mode Siemens PLC control + Explosion-proof touch screen

10. Pre-filter: efficiency G4, non-woven

11. Medium efficiency filter: efficiency F8, bag type

12. High efficiency HEPA filter: efficiency H14, gel seal without partition (high efficiency with PAO detection port)

13. Explosion-proof differential pressure speed gauge (American Setra brand)

14. The exhaust vents are equipped with HEPA filters

15. Front hanging detachable door curtain

16. Explosion-proof wind speed sensor (SCHMIDT)

17. Factory set 3 level password

18. Explosion-proof description: Explosion-proof level: II B-T4 Gb

Only explosion-proof fans, explosion-proof lights, explosion-proof sockets, explosion-proof electrical boxes, explosion-proof switches, explosion-proof wind speed sensors, explosion-proof pressure difference transmitters, all wires are connected by explosion-proof pipes.

|

16 |

Explosion-proof wind speed sensor |

0-2m |

1 |

SCHMIDT |

|

15 |

Explosion-proof LED lamp |

Panel light |

2 |

Zhonggong Tongming |

|

14 |

Start switch |

YJ-GQ16H-11 |

1 |

ZK |

|

13 |

E-stop |

Schneider Electric |

1 |

Schneider |

|

12 |

Explosion-proof electrical box |

SUS304 |

1 |

Huice / Chuangxin |

|

11 |

Explosion-proof socket |

IP55 220V |

4 |

Ronghua |

|

10 |

Explosion-proof touch screen |

7 inches XY500 |

1 |

Xuyong |

|

9 |

Primary efficiency filter |

G4 |

2 |

Anne Parker |

|

8 |

Medium efficiency filter |

F8 |

2 |

Anne Parker |

|

7 |

Gel seal HEPA filter |

H14 (air exhaust) |

2 |

Anne Parker |

|

6 |

Gel seal HEPA filter |

H14 (air supply) |

2 |

Anne Parker |

|

5 |

Detection port |

6-point clamp |

2 |

304#SUS |

|

4 |

Injection port |

6-point clamp |

2 |

304#SUS |

|

3 |

Explosion-proof differential pressure speed gauge |

0-250Pa |

2 |

American Setra |

|

0-500Pa |

1 |

|||

|

2 |

Frequency changer |

Sanqian brand |

1 |

380V |

|

1 |

Explosion-proof fan |

DKT 9-56 |

2 |

Shanghai Yingda |

|

No. |

Designation |

Specification/Model |

Qty. |

Notes |