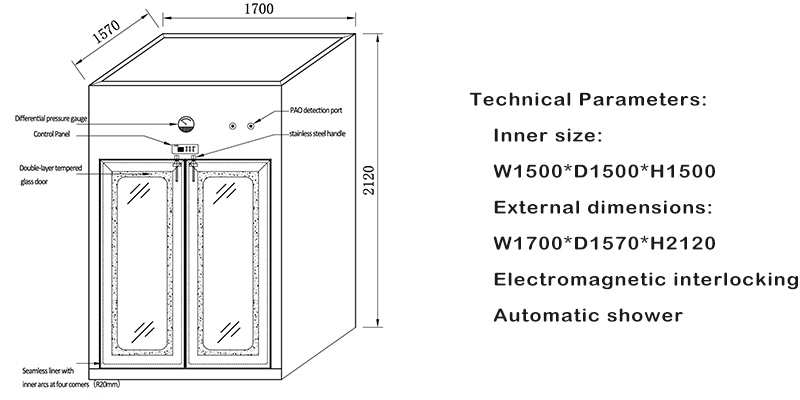

Technical Parameters:

1. Inner size: W1500*D1500*1500

External dimensions: W1700*D1570*H2120

2. Electromagnetic interlock

3. Automatic blowing

4. Gel seal HEPA filter: aluminum frame without partitions

Pass box in pharmaceutical industry Technical Parameters:

1. Inner size: W1500*D1500*1500

External dimensions: W1700*D1570*H2120

2. Electromagnetic interlock

3. Automatic blowing

4. Gel Seal HEPA filter: aluminum frame without partitions

Filtration efficiency: (H14)99.99%@0.3uM

5. Centrifugal fan: 310

6. Wind speed 0.36-0.54m/s

7. Box material: 1.2mm/304# sanded stainless steel plate, natural sanded surface

8. Inner wall material: 12mm/304# sanded stainless steel plate, surface naturally sanded

9. The operation panel must display the blowing time (adjustable from 0-99 minutes) and the cumulative sterilization time counting function. The counting time function can only be seen by dicking on the operation interface. Please refer to the manual for specific functions!

10. Power: 220V/50H20.3KW

Pass box in pharmaceutical details

|

1 |

Motor |

4 sets |

310# |

XM |

|

2 |

Sterilization lamp |

2 |

460mm |

KX |

|

3 |

Differential pressure gauge |

1 set |

0-500pa |

Duwei |

|

4 |

Injection port |

1 set |

6 points clamp |

SUS 304 |

|

5 |

Detection port |

1 set |

6 points clamp |

SUS 304 |

|

6 |

Gel seal HEPA filter |

1 |

Pcs |

AN |

|

7 |

Control panel |

1 |

CLCDC |

AN |

|

8 |

Stainless steel handle |

2 sets |

SUS 304 |

AN |

|

9 |

Tempered glass |

1 |

Pcs |

AN |

Dynamic pass-through box clean room in pharma

Description: Dynamic pass box in pharma is a type of cleanroom auxiliary equipment, mainly used for transferring small items between clean rooms and non-clean areas, or between clean rooms of different levels and pressures. On the one hand, it acts as an airlock to prevent high pressure in higher-level clean rooms from being released. On the other hand, it achieves a self-cleaning effect during the transfer process to ensure the cleanliness of items entering the clean area and reduce cross-contamination brought by objects; the blowing time can be adjusted arbitrarily according to the manual switch, to achieve maximum blowing and energy-saving effects.