The dispensing booth vertical one-way air flow continuously circulates in the main work area to effectively control the overflow and rise of powder, prevent the harm of inhalation to the human body, and avoid cross-contamination to protect the environment and the safety of indoor personnel.

Sampling and Dispensing Booth Weighing Room Specifications

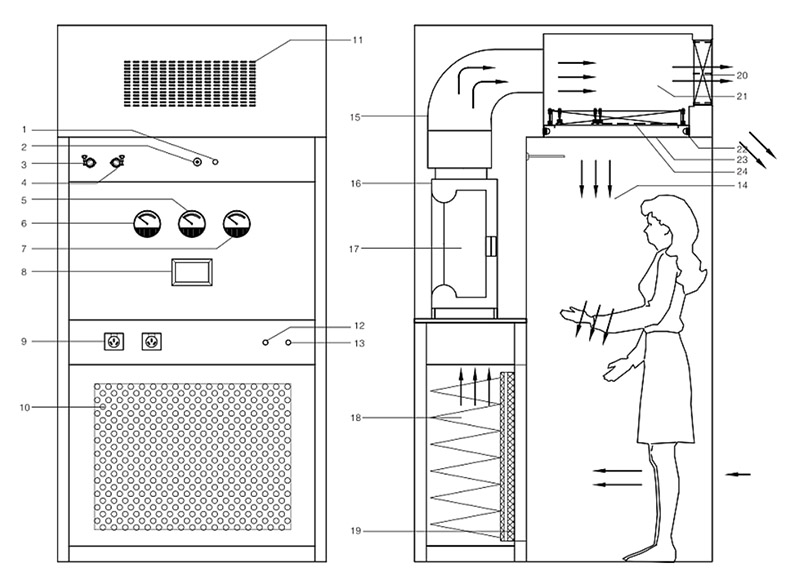

The negative pressure raw material sampling booth is composed of work area, return air box, fan box, outlet box, outer box, supply air HEPA filter, exhaust air HEPA filter, variable air volume air unit, PLC control system and sensing system. The control panel is located in the front of the working area inside the weighing room equipment. The control panel adopts the touch screen control panel, which can control the start and stop of the fan, adjust the working condition of the fan, and adjust the wind speed required by the working area. There is a differential pressure gauge beside it to test the resistance of the filter. There is an exhaust air adjustment plate inside the air supply box, which can adjust the exhaust air volume of the sampling and dispensing booth in pharmaceutical industry equipment within a reasonable range.

Weighing room in laboratory Instruction

1. Buzzer 2. Wind speed sensor 3. PAO injection port 4. DOP detection port 5. Medium effect differential pressure table 6. Initial effect differential pressure table 7. High efficiency differential pressure table 8. Centralized control panel 9. Dust-proof socket 10. Return air mesh panel 11. Exhaust air mesh 12. Start button 13. Emergency stop 14. Negative pressure area 15. Air duct 16. Fan box 17. Fan 18. Bag filter 19. Primary filter 20. Tank high efficiency 21. Positive pressure zone 22. Lighting fixture 23. Flow film 24. Gel seal efficient

Dispensing booth pharmaceutical industries specifications

|

Model |

External dimension (mm) |

Work area size (mm) |

Rated air flow (m³) |

Wind speed (m/s) |

Cleanliness class |

Noise (dB) |

Illuminance (Lux) |

Control way |

Power (KW) |

|

AN-CLS 1200 |

1200*1200*2500 |

1100*700*2000 |

1300~1500 |

0.45±20% |

Class A |

72 |

≥300 |

Inverter control / LCD control |

0.75 |

|

AN-CLS 1300 |

1300*1300*2500 |

1200*800*2000 |

1600~1800 |

0.75 |

|||||

|

AN-CLS 1400 |

1500*1300*2500 |

1400*700*2000 |

2000~2200 |

1.5 |

|||||

|

AN-CLS 1500 |

2000*1300*2500 |

1900*800*2000 |

2500~2700 |

1.5 |

|||||

|

AN-CLS 1600 |

2000*1500*2500 |

1900*1300*2000 |

3400~3600 |

2.2 |

|||||

|

AN-CLS 2700 |

2000*1800*2500 |

1100*700*2000 |

4500~4900 |

2.2 |

Note: The dispensing booth specifications listed in the table are for customer's reference only, and the negative pressure dispensing booth design can be designed and manufactured according to the customer's URS document.

Sampling dispensing booth Advantages

1. Fan with long life, low noise, maintenance-free, small vibration;

2. Double-layer negative pressure structure, no leakage risk;

3. Excellent air uniform distribution performance;

4. Automatic constant or graded adjustment of wind speed;

5. Tank design ensures perfect seal;

6. Consistent inside and outside, clean and no dead corners;

Powder dispensing booth Application