The AN-HVAC series VHP sterilizer adopts flash vaporization technology, which vaporizes 30%-35% hydrogen peroxide and then quickly and evenly distributes it in the sterilization space through the HVAC system, realizing space 6LOG sterilization without dead end; after the sterilization, the hydrogen peroxide can be rapidly degraded with no residue and no toxicity.

| AN-3000 Parameter table | |

| Model | AN-3000HVAC |

| Dimensions(W*H*D) | 1800*2000*800 |

| Vaporization rate | 20-160ML/min |

| Power | 30Kw |

| Air supply volume | 100-1000cmh |

| Sterilization time | 60-360min |

| Weight | 150Kg |

Sterilization principle and features

The AN-HVAC series VHP sterilizer adopts flash vaporization technology, which vaporizes 30%-35% hydrogen peroxide and then quickly and evenly distributes it in the sterilization space through the HVAC system, realizing space 6LOG sterilization without a dead end; after the sterilization, the hydrogen peroxide can be rapidly

degraded with no residue and no toxicity. The system adopts a modular design with four parallel groups of VHP generation modules to ensure the reliability of the system; the sterilization process is controlled by saturation and dew point to ensure the vaporization state of hydrogen peroxide. The overall equipment is made of

stainless steel, which is smooth in appearance without dead ends; through the user-friendly operating interface, users can quickly master the operating skills; the system's project management and implementation team can provide services from design, production, installation, commissioning, parameter development to verifica-tion, and can complete turnkey projects in the field of pharmaceutical, biosafety. medical and public safety.

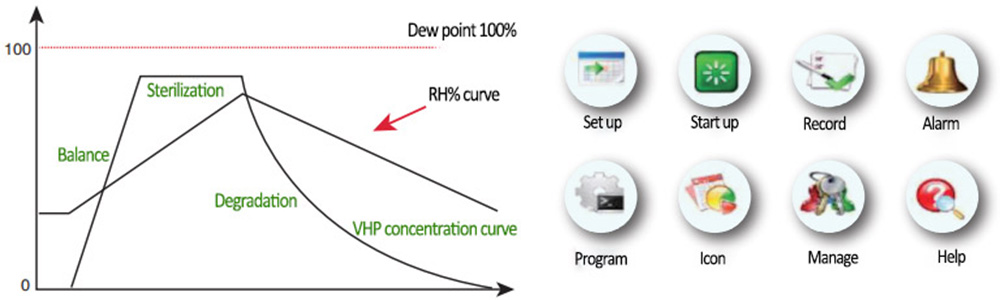

Sterilization Curve

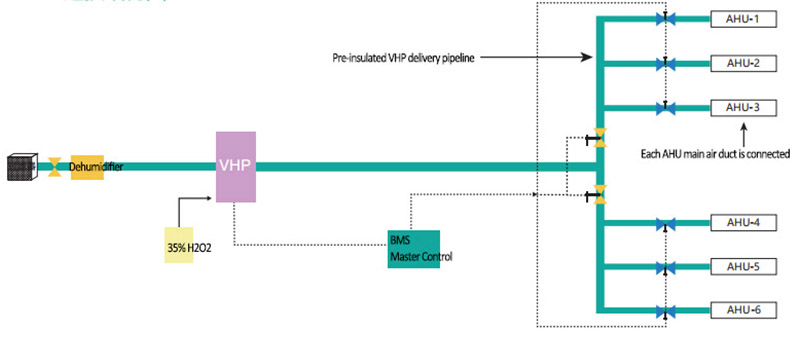

HVAC Connection structure diagram

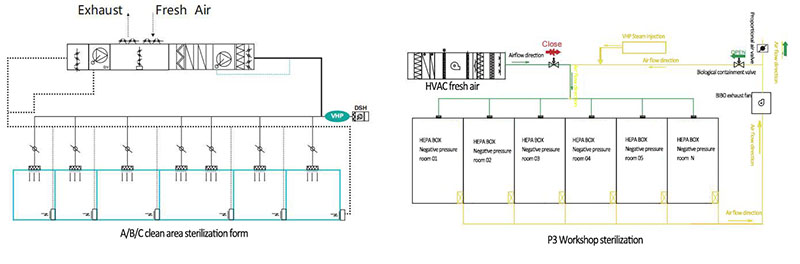

Installation and connection method

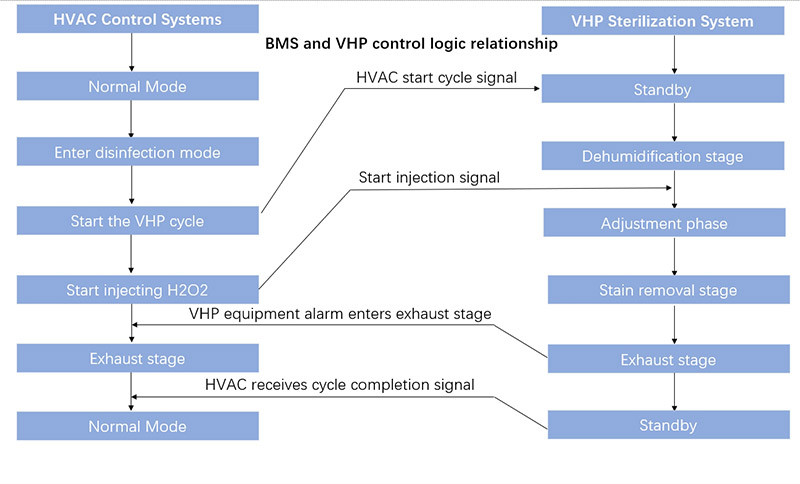

Control logic of HVAC sterilization system