For surface disinfection and low-temperature surface sterilization Applications of a VHP generator

Isolator VHP generator is suitable for low-temperature surface sterilization in small confined spaces, providing a closed sterilization loop to achieve sterilization and

degradation in one piece of equipment. This sterilization method complies with FDA and GMP guidelines.

The sterilization is realized by using VHP sterilant, without residue. The generator is designed to be used in validated GMP processes.

Other small airtight space

Principle of VHP generator

We use low-temperature flash vaporization technology to achieve complete vaporization of hydrogen peroxide:

The process saturation control technology is adopted to realize no liquefaction and no condensation in the whole process of sterilization;

The process monitoring parameters include temperature, relative humidity, hydrogen peroxide concentration, and vapor saturation:

The adjustment parameters include: flash temperature, circulating air volume, and peristaltic pump injection rate:

The safety control parameters include hydrogen peroxide concentration, saturation, and hydrogen peroxide residual concentration:

The VHP generator is integrated with the catalytic degradation, making sterilization more convenient and faster.

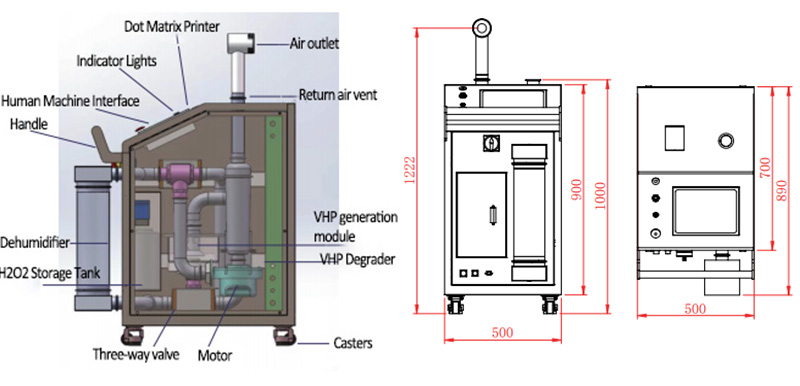

| VHP generator | |

| Sterilization Space(m³) | 0-200m³ |

| Hydrogen Peroxide Concentration Range | 0-2000ppm |

| Hydrogen Peroxide Vaporization Rate | 0-15m/min |

| External Dimensions(w*h*d) (mm) | 500mm*900mm*700mm |

| MAX Power(W) | 2000W |

| Power Supply | 220V,50Hz |

Drawing of the VHP generator

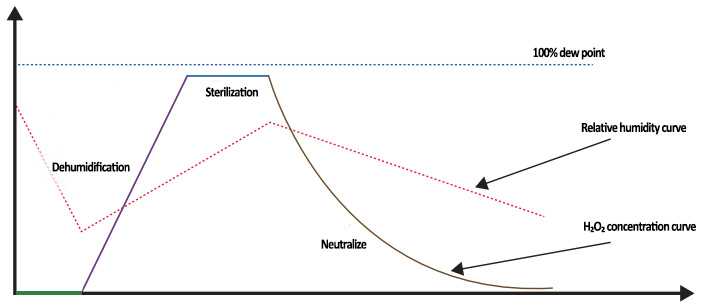

VHP Sterilization Curve