By utilizing an integrated VHP from generator, the pass box ensures the sterilization of non-exposed surfaces within a low-temperature or ambient temperature environment. This sterilization process is environmentally friendly, efficient, thorough, and safe.

VHP Pass Box Suppliers in Pharma Clean Room

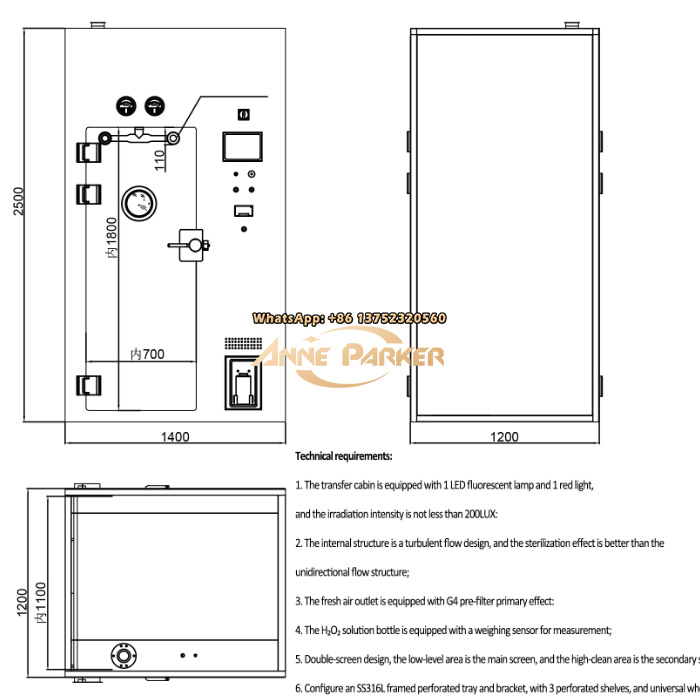

VHP pass box Technical requirements:

1. The vhp pass box clean room is equipped with 1 LED fluorescent lamp and 1 red light, and the irradiation intensity is not less than 200LUX;

2. The internal structure of vhp pass box in pharma is a turbulent flow design, and the sterilization effect is better than the unidirectional flow structure;

3. The fresh air outlet is equipped with G4 pre-filter primary effect:

4. The H2O2 solution bottle is equipped with a weighing sensor for measurement;

5. Double-screen design, the low-level area is the main screen, and the high-clean area is the secondary screen;

6. Configure an SS316L framed perforated tray and bracket, with 3 perforated shelves, and universal wheels at the bottom.

|

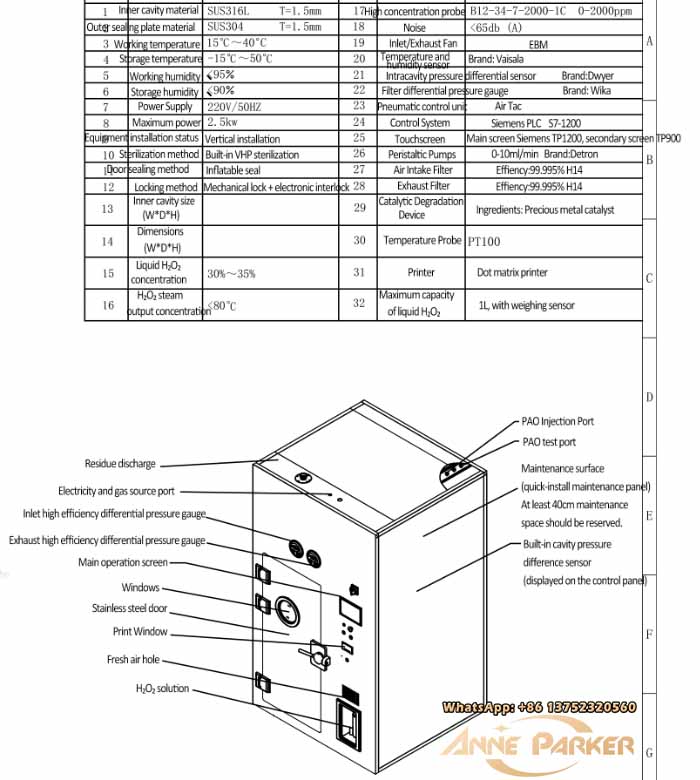

1 |

Inher cavity material |

SUS316L T=1.5mm |

17 |

High concentration probe |

B12-34-7-2000-1C 0-2000ppm |

|

2 |

Outer sealing plate material |

SUS304 T=1.5mm |

18 |

Noise |

<65db(A) |

|

3 |

Working temperature |

15℃~40°C |

19 |

Inlet/Exhaust Fan |

Forward centrifugal fan; Brand: EBM |

|

4 |

Stprage temperature |

-15℃~50℃ |

20 |

Temperature and humidity sensor |

Brand: Vaisala |

|

5 |

Working humidity |

≤95% |

21 |

Intracavity pressure differential sensor |

Brand: Dwyer |

|

6 |

Storage humidity |

≤90% |

22 |

Filter differential pressure gauge |

Brand: WIKA |

|

7 |

Power Supply |

220V / 50HZ |

23 |

Pneumatic control unit |

Brand: Air Tac |

|

8 |

Maximum power |

2.5kw |

24 |

Control System |

Siemens PLC S7-1200 |

|

9 |

Equipment installation status |

Vertical installation |

25 |

Touch screen |

Main screen Siemens TP1200, secondary screen TP900 |

|

10 |

Sterilization method |

Built-in VHP sterilization |

26 |

Peristaltic Pumps |

0-10ml/min Brand: Detron |

|

11 |

Doorsealing method |

Inflatable seal |

27 |

Air Intake Filter |

Effiency: 99.995% H14 |

|

12 |

Locking method |

Mechanical lock+electronic interlock |

28 |

Exhaust Filter |

Effiency: 99.995% H14 |

|

13 |

Inner cavity size (W*D*H) |

700*1100*2500mm |

29 |

Catalytic Degradation Device |

Ingredients:Precious metal catalyst |

|

14 |

Dimensions (W*D*H) |

1400*1200*1800mm |

30 |

Temperature Probe |

PT100 |

|

15 |

Liquid H2O2 concentration |

30%~35% |

31 |

Printer |

Dot matrix printer |

|

16 |

H2O2 steam output concentration |

<80℃ |

32 |

Maximum capacity of liquid H2O2 |

1L, equiped with weighing sensor |

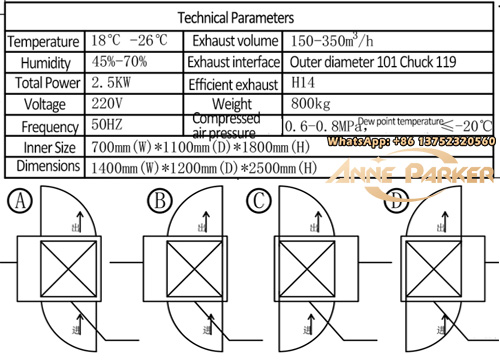

As we are professional vhp pass box suppliers, size and style can be customized according to customer's requirements.