1. Cleanliness requirements in pass box stainless: Class A;

2. Double shell inside and outside, circular arc treatment around the inside to ensure seamless connection;

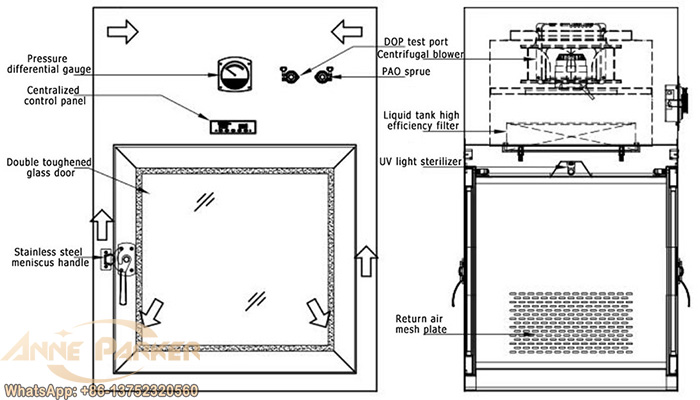

3. Adopts laminar flow design, the airflow direction adopts the mode of up and down, the bottom adopts 304 stainless steel cold-rolled plate punching design, and the reinforcement is set.

Types of Dynamic Pass Box Stainless in Pharma Manufacturer

Types of pass box in pharma Basic performance requirements:

1. Cleanliness requirements in dynamic pass box in pharma: Class A;

2. Double shell inside and outside, circular arc treatment around the inside to ensure seamless connection;

3. Adopts laminar flow design, the airflow direction adopts the mode of up and down, the bottom adopts 304 stainless steel cold-rolled plate punching design, and the reinforcement is set;

4. Filter: the primary efficiency filter is G4, the high efficiency filter is H14;

5. Wind speed: After the HEPA filter, the outlet wind speed is controlled at 0.36-0.54m/s (tested at 150mm below the high-efficiency outlet flow average plate);

6. Differential pressure function: display filter differential pressure (range efficiency 0-500Pa/ medium efficiency 0-250Pa), accuracy ±5Pa;

7. Control function: blower start/stop button, equipped with built-in electronic door interlock; Set UV lamp and design with separate switch;

8. The access port is set at the lower part of the pass box stainless for the maintenance of the blower;

9. Noise: Noise < 65db during normal operation of the dynamic pass box in pharma;

10. Efficient airflow distribution plate: using 304 stainless steel mesh plate.

11. Customized all types of pass box in pharma by professional dynamic pass box manufacturers.