Mist air shower is used in special environments such as laboratories or workshops to ensure that active or toxic dust particles adhering to the surface of clean clothing are removed by mist during the production process or when personnel leave the workshop after the production.

Cleanroom Stainless Steel Mist Air Shower Supplier

Mist air shower is used in special environments such as laboratories or workshops to ensure that active or toxic dust particles adhering to the surface of clean clothing are removed by mist during the production process or when personnel leave the workshop after the production.

At present, in most pharmaceutical production industries and other high-risk and high-pollution enterprises, high-pollution products (for operators) more and more, staff will operate these high-pollution powder materials, and attached to protective clothing, in order to avoid harming the operator and the external environment, must take protective measures.

The mist air shower can effectively and comprehensively spray the water mist evenly on the surface of the clothes, and attach the small water beads to the surface of the clothes to prevent dust. The mist air shower is equipped with different cleaning methods to cope with different situations and ensure the effectiveness of the equipment.

The mist air shower is equipped with efficient exhaust vents to replace the air in the mist air shower and form negative pressure at the same time to prevent the spill of harmful substances in the mist air shower and possible residual to other areas.

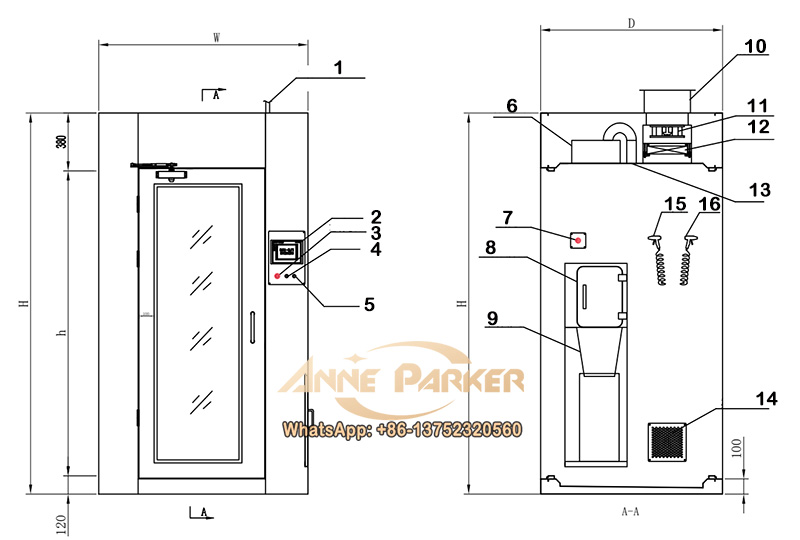

1. Water inlet reserved 25 pipe diameter quick mounting chuck interface 2. Touch screen 3. Emergency stop button 4. Buzzer 5. Door opening button 6. Atomization system 7. Emergency stop button 8. Clothes dump door 9. Clothes chute 10. Air vent 11. Exhaust fan 12. Efficient exhaust 13. Spray port 14. Atomizing return air port 15. Dust blow gun 16. Water gun

Mist air shower Characteristics

1. To enter the door, press the door button to enter, to prevent accidental opening and closing

2. In addition to the atomizing device, it is also equipped with hand-held water guns and air guns, which can cope with the cleaning methods required by different parts and different needs, and is more humane

3. Ultrasonic atomization system, atomization is delicate, so that the water mist can be evenly sprayed on the staff's clothing, the dust together with the fog droplets are adhered to the clothing, so that the staff can not shake off the dust when undressing, protecting the personal safety of the staff

4. Compared with the traditional water pressure and water gas mixed spray, the comfort of personnel is greatly improved, and the situation that water is easy to form in each area is effectively avoided

5. Shadow storage waste clothing collection bucket (side alley), beautiful and convenient

6. Hidden door frame, more beautiful appearance

7. Inside around the slope transition, beautiful, easy to clean

8. With programmable PLC, the work is completely automatic and the time is adjustable

Work flow

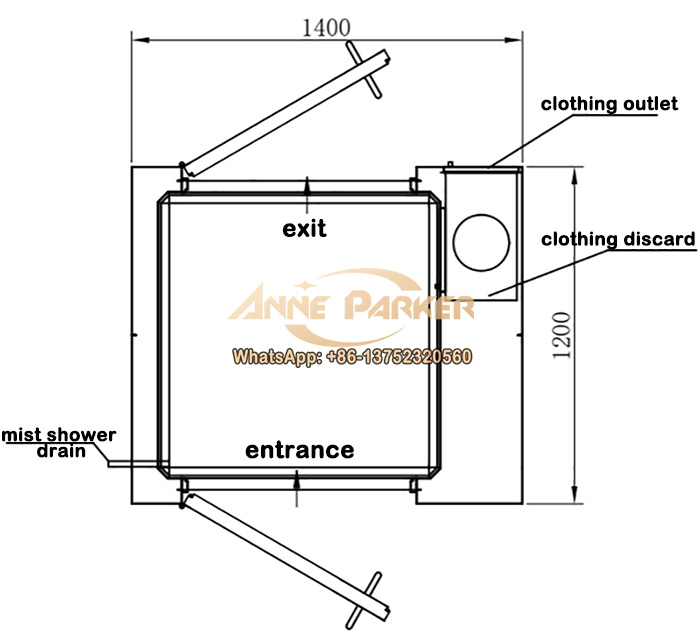

1. Press the open door button to enter the mist air shower room, and the door automatically closes and locks.

2. The mist air shower atomizing system works automatically according to the set time.

3. After the atomization is finished, go out to unlock the door, take off the protective clothing, and put it in the waste clothing collection bucket.

4. Open the door, personnel out of the mist air shower and close the door, the door is locked.

5. After the exhaust system is completed according to the set time, the mist air shower is restored to the initial state.

Organizational structure

Four system components: envelope structure, water system, spray system, automatic control system

1. Enclosure structure: The use of 304 stainless steel material assembly molding, each mist air shower is independent of each other

2. Water system: composed of pipes, valves, sensors, etc., to supply water to the mist air shower

3. Spray system: ultrasonic atomization system, water mist is fine

4. Automatic control system: by PLC, LCD screen and related automatic control original group

Working principle of atomization system

1. When the mist air shower starts, the atomizer and atomizer start at the same time

2. Air is pumped from the inside of the spray through the atomizing auxiliary fan and sent to the atomizing water tank along the pipeline

3. The mist in the atomizing water tank is brought out by the wind, and is sent through the pipe to the mist air shower

Working principle of exhaust fan

The exhaust fan starts when the door is opened to enter the mist air shower. (forming negative pressure)

Mist air shower atomizing system is closed when working. (To prevent the discharge of fog, affecting the fog effect)

Start after the end of atomization, until the personnel out of the fog shower and close the door 5 minutes after closing. (Forming negative pressure, discharging indoor air, ensuring indoor air pollution-free.)

Note: Can be customized with high specifications: high efficiency exhaust or BIBO exhaust filter + airtight door sealing type.