Dynamic VHP pass box is primarily used for the transfer of materials between sterile inspection laboratories, microbiology laboratories, positive control laboratories, and material transfer rooms in pharma, sterilization of material packaging and external surfaces.

VHP Pass through Box in Pharma

I. Introduction

As an auxiliary equipment in the clean room, the pharmaceutical pass box in pharma is mainly used for the transfer of small items between the clean area and the clean area, and between the unclean area and the clean area, to reduce the number of doors in the clean room and minimize the pollution in the clean area. The VHP pass box is widely used in microtechnology, biological laboratories, pharmaceutical factories, hospitals, the food processing industry, LCD, electronics factories, and other places that need air purification.

The VHP pass box is made of a stainless steel plate. Two doors interlocking each other, effectively prevent cross-contamination, with electronic or mechanical interlocking devices, and equipped with ultraviolet sterilization lamps.

II. Classification

The types of pass box in pharma are divided into three categories: electronic chain pass box, mechanical chain pass box, self-cleaning pass box

According to the working principle, the VHP pass-through can be divided into air shower pass box, ordinary pass box and laminar flow pass box. Various types of VHP pass boxes can be made according to actual requirements.

Optional accessories: walkie-talkie, germicidal lamp and other related functional accessories.

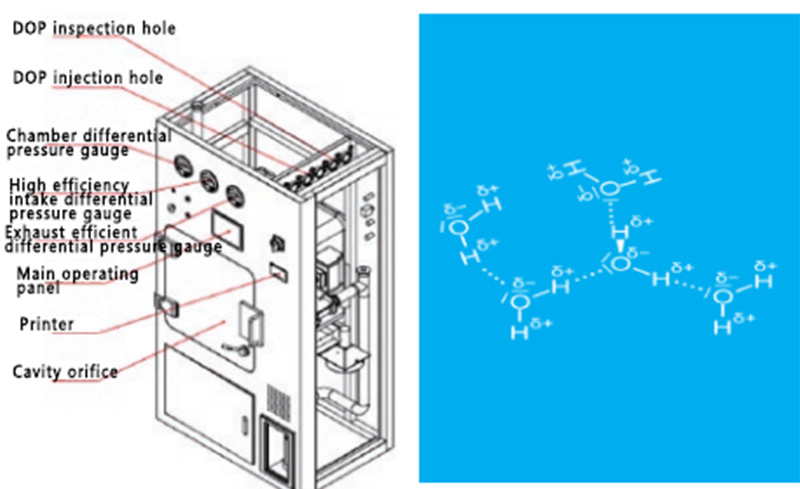

By utilizing an integrated VHP from the generator, the VHP pass box ensures the sterilization of non-exposed surfaces within a low-temperature or ambient temperature environment. This sterilization process is environmentally friendly, efficient, thorough, and safe.

III. Characteristics

1. Short-distance dynamic pass box working table made of stainless steel plate, smooth, clean and wear-resistant.

2. Long distance dynamic pass box work table with no power roller, easy to transfer items

3. Both sides of the door are equipped with mechanical interlock or electronic interlock, electronic locking device to ensure that both sides of the door can not be opened at the same time.

4. According to customer needs, customized various non-standard sizes and floor-to-ceiling VHP box.

5. The wind speed of the air nozzle outlet is above 20s.

6. Adopt HEPA filter with separator, filtration efficiency is 99.99%, to ensure the purification level.

7. EVA sealing material, high sealing performance.

8. Call intercom can be paired.

IV. Working principle

1. Mechanical interlocking device: the internal use of mechanical form to achieve interlocking, when a door is opened, another door can not be opened, you must close another door and then open another door.

2. Electronic interlock device: the internal integrated circuit, electromagnetic lock, control panel, indicator light, etc., to achieve interlock, when one of the doors is opened, the door of the other door is not lit, telling the door can not be opened, while the electromagnetic lock action to achieve interlock. When the door is closed, the electromagnetic lock of the other door begins to work, and the indicator light will light, indicating that the other door can be opened.

Technical parameters

|

Model |

Inner size (W*D*H) |

External size (W*D*H) |

Power (kw) |

Weight (kg) |

|

HPB-216 |

600*600*600mm |

1050*650*1800mm |

2.0 |

280 |

|

HPB-288 |

600*600*800mm |

1050*650*2000mm |

2.2 |

300 |

|

HPB-360 |

600*1000*600mm |

1050*1050*1800mm |

2.2 |

320 |

|

HPB-512 |

800*800*800mm |

1250*850*2000mm |

2.3 |

350 |

|

HPB-640 |

800*800*1000mm |

1250*850*2200mm |

2.5 |

360 |

|

HPB-800 |

800*1000*1000mm |

1250*1050*2200mm |

2.6 |

380 |

|

HPB-960 |

800*1000*1200mm |

1450*1250*2150mm |

2.8 |

400 |

|

HPB-1536 |

800*1200*1600mm |

1450*1250*2150mm |

3.0 |

450 |

|

HPB-1792 |

800*1400*1600mm |

1450*1450*2150mm |

3.2 |

480 |

|

HPB-2688 |

1200*1400*1600mm |

1850*1450*2150mm |

4.0 |

600 |

|

Note: The above are standard products, non-standard products can consult our sales staff, we can provide non-standard customized products according to customer requirements. |

||||

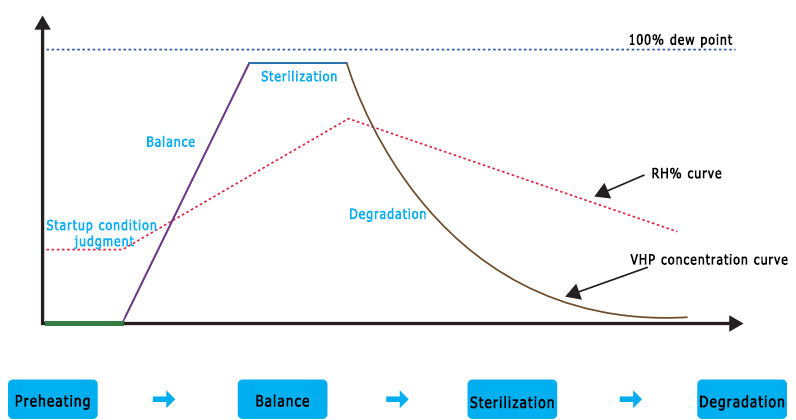

█ STERILIZATION PROCESS

Preheating: The temperature and humidity conditions of the chamber are automatically adjusted before the equipment is started to achieve the set program start conditions.

Balance: The sterilization conditions are started, and the device performs self-balancing of VHP concentration and saturation to achieve sterilization conditions.

Sterilization: Start sterilization and accumulate the LOG value of sterilization until the end of sterilization.

Degradation: After sterilization, the equipment enters the exhaust degradation stage, and VHP is discharged and degraded until the end of the procedure.