1. Using knowledge

I. Classification

Cleanroom dynamic pass box transfer hatch according to the use can be divided into dynamic pass box and pass through hatch these two categories. Dynamic pass box in pharma is mainly used for the transfer of goods in a clean environment, requiring HEPA filter filtration to achieve clean effect; The clean room pass through hatches is suitable for the isolation and transmission of dangerous substances such as microorganisms and bacteria, and has the functions of anti-leakage and anti-proliferation.

II. Structure

The transfer hatches for clean room pass box in pharmaceutical industry is mainly composed of box, HEPA filter, ultraviolet lamp (pass box uv), stainless steel partition, caster and so on. The HEPA filter is the core component of the cleanroom transfer hatch, which can effectively filter the dust particles in the air to ensure cleanliness; Ultraviolet lamps are used to kill microorganisms that may be present and ensure the safety of the transmitted goods.

III. Working principle

When the active pass-box pass-through hatch is working, the air in the box is filtered by the HEPA filter to form a clean air layer, and the items in the cleanroom pass-through hatches are isolated from the outside environment. Items can be transferred through the window while avoiding the surface of the goods by the external environment pollution. Ultraviolet lamps can effectively kill microorganisms that may exist, ensuring the cleanliness and safety of goods.

IV. Installation and use

The pharmaceutical pass-through box clean room should be installed in the laboratory or production workshop where the airflow is relatively clean to minimize the impact of air disturbance on cleanliness. During installation, the tightness between the pass box and the wall should be ensured, and the supporting facilities such as the power supply and compressed air should be perfected. When used, it should follow the principle of opening first and closing later, that is, opening the door of the cleanroom transfer hatch first, and then putting the items into the pass-through hatches; The opposite is true when closed. At the same time, the clean room pass-through hatches should be cleaned and maintained regularly to keep them in good working condition.

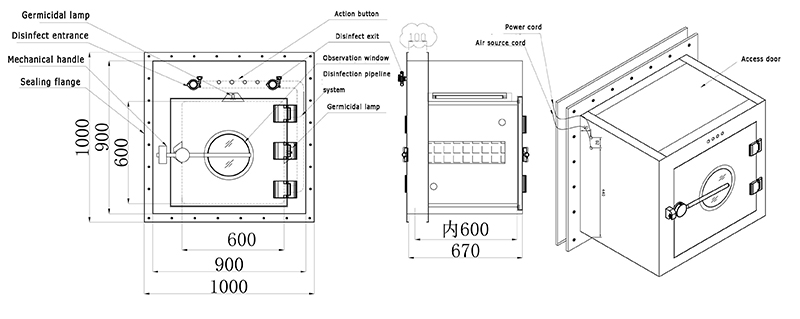

Product name: dynamic pass box pass through hatch clean room

Specification: W900xD670xH900mm (outside) (excluding sealing method)

M600xD600 xH600mm(inner)

Material and technical description:

1. The cabinet shell is made of national standard t1.5mm 304 stainless steel sanded plate, and the cabinet is made of national standard t1.5mm 316L stainless steel mirror panel with seamless arc design at the four corners;

2. The entire equipment adopts mechanical seal design + inflatable seal;

3. The door is equipped with a circular observation window;

4. Be equipped with a special control system for the transfer hatches for clean room and double-door electromagnetic interlocking;

5. There are 3 germicidal lamps inside, one on the top and one on the left and right walls;

|

Inner cavity material |

SUS316 |

|

External sealing board material |

SUS304 |

|

Temperature |

15℃~55℃ |

|

Storage temperature |

-15℃~50℃ |

|

Working humidity |

≤95% |

|

Storage humidity |

≤90% |

|

Power |

220V 50Hz |

|

Temperature |

15~50℃ |

|

Humidity |

45%~70% |

|

Power |

0.2kw |

|

Voltage |

220V |

|

Frequency |

50Hz |

|

UV rays |

>70uw/cm² |