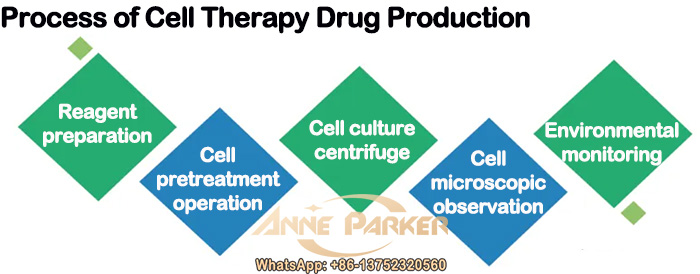

The cell therapy isolator is to put the process of cell therapy drug production in a completely closed area, including reagent preparation, cell pretreatment operation, cell culture centrifugation, cell microscopic observation, environmental monitoring and other processes.

Cell Therapy Isolator Clean Room Equipment Manufacturer

With the deepening of cell therapy in the world, more and more difficult diseases have begun to rely on this advanced technology, including the new coronavirus pneumonia, the application of cell therapy has also emerged.

At the same time, traditional pharmaceutical aseptic isolators have also penetrated into the field of cell therapy, and isolators dedicated to the production of cell drugs have emerged. The new darling of cell therapy.

The cell therapy isolator is to put the process of cell therapy drug production in a completely closed area, including reagent preparation, cell pretreatment operation, cell culture centrifugation, cell microscopic observation, environmental monitoring and other processes.

Compared to the traditional model

Economic: Class D clean room installation conditions, reduce maintenance and operating costs, no specific consumables, no strictly trained professionals.

Stable: The cell production environment is easy to control and monitor, the working area conditions are stable, the cell growth is uniform and synchronous, and the cell products are stable and the quality is controllable.

Safety: Intelligent, modular design, get rid of the traditional clean room trouble, positive pressure protection in the work area, always in A class A cleanliness environment, real-time monitoring of environmental conditions can be traced.

Fast: Reduce sample handling time, delivery time, quality control time, automatic H202 fumigation simplify sterilization process.

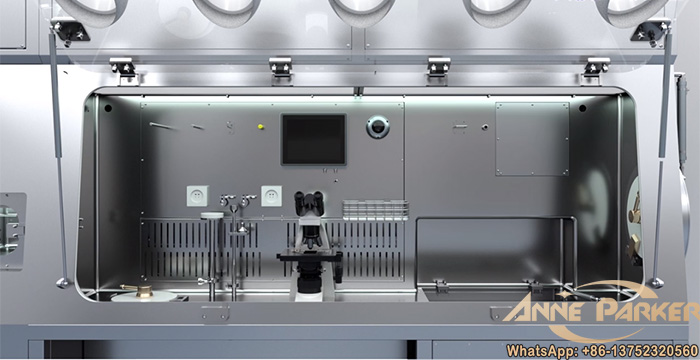

The cell therapy isolation workstation is also structurally composed of a transfer hatch and an operation module. The transfer compartment acts as a small isolator, achieving Class A cleanliness within two minutes of being turned on, while a dust particle counter and a plankton collector continuously monitor environmental cleanliness. After reaching Class A cleanliness, the transfer hatch door is opened, and samples and reagents are transferred to the operating compartment by electric tray. The whole process of cell production is completed with the help of built-in C02 incubator, microscope, centrifuge, cell counter and other instruments. The whole process is monitored and managed by SCADA system to ensure traceability.

· Integrated process equipment such as centrifuge and microscope

· Stable cell culture environment

· Can be equipped with suspension concussion culture equipment

· Whole data traceability system

· Product sample independent control

· Can be fully WiFi control